Gas zu flüssigem Kraftstoff & Brennstoff !

what we offer is "renewable"

The main objective of different regions is gaining energy independence, meaning to be able to produce alternative energy sources (fuel) on their own territory, preferably, with no waste, thus simultaneously solving ecological problems. Companies offering this kind of product will find themselves in more favorable conditions, since market competition is not there. Many countries in their time solved this problem using agricultural products for fuel production. However, the return was not high as at that time the process automation and optimization were on a very low level. Nowadays, computing and state–of–the–art technologies provide the opportunity of making the synthesis processes of different fuel kinds more efficient. It has caused a drastic growth in productive efficiency.

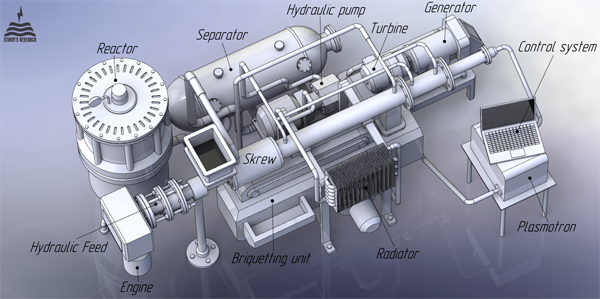

The research and development laboratory of STORM’s offers the designing, development, production, installation and technology transfer of "STORMiCO TM gas–to–liquid" and "garbage to fuel" plant(s) (for producing alternative fuel sources). The plant is intended for carbonaceous waste reprocessing, oil–polluted soil and water bodies restoration, as well as discharged water cleaning. It is also designed for production of different kinds of synthetic fuel and heat, electricity and distilled water. The "STORMiCO TM plant" covers rather vast branches of the modern market off–load for it helps to solve the issues affecting practically every human our activity areas.

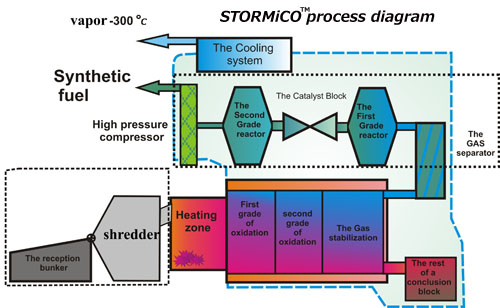

Plant operation principle diagram of the "STORMiCO TM process"